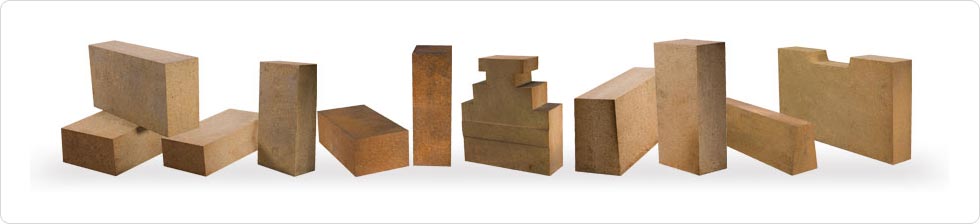

PRODUCTS - High Alumina Bricks |

| Brand Name |

Al2O3

(%)

Min |

Fe2O3

(%)

Max |

A.P. (%)

Max |

B.D.

(gm/cc)

Min |

CCS

(kg/cm2)

Min |

PLC

(%)

Max. |

PCE

(SK)

Min |

RUL

Ta(0C)

Min |

Application Area |

| SR -62 D |

62 |

1.20 |

16 |

2.50 |

600 |

± 0.20

at 15000C/ 2 hrs |

36 |

1550 |

Blast furnace hearth & tuyere |

| SR 62 LF |

62 |

1.2 |

18 |

2.52 |

500 |

± 0.3

at 15000C/ 2 hrs |

36 |

1600 |

Blast Furnace checkers |

| SR-70 LF |

70 |

1.5 |

20 |

2.60 |

500 |

± 0.3

at 15000C/ 2 hrs |

36 |

1550 |

Rotary Kiln Lining |

| SR-Mul -70 S |

70 |

0.80 |

20 |

2.50 |

500 |

± 0.20

at 15000C/ 2 hrs |

36 |

1700 |

Blast Furnace hearth & tap hole, glass tank furnace |

| SR-Mul-70 (F) |

70 |

0.5 |

17 |

2.55 |

600 |

± 0.20

at 15000C/ 2 hrs |

36 |

1720 |

Blast Furnace hearth & tap hole, glass tank furnace |

| SR-70 B (LF) |

70 |

2.5 |

20 |

2.60 |

500 |

± 0.30

at 16000C/ 2 hrs |

36 |

1480 |

EAF roof, ladle |

| SR -70 B |

70 |

3.0 |

22 |

2.55 |

450 |

± 0.30

at 16000C/ 2 hrs |

35 |

1440 |

EAF roof |

| SR-80B (LF) |

80 |

2.5 |

20 |

2.70 |

500 |

± 0.30

at 16000C/ 2 hrs |

37 |

1500 |

-do- |

| SR -80 B |

80 |

3.0 |

22 |

2.70 |

500 |

± 3.0

at 16000C/ 2 hrs |

35 |

1460 |

-do- |

| SR-85 TAB |

84 |

1.5 |

20 |

2.70 |

700 |

± 0.5

at 15000C/ 2 hrs |

37 |

1580 |

Aluminum melting & holding furnace. |

| SR-85 D |

85 |

1.5 |

20 |

2.90 |

500 |

±0.5

at 15000C/ 2 hrs |

37 |

1650 |

Torpedo ladle lining |

| SR 88 NF |

88 |

2.0 |

18 |

2.85 |

800 |

± 0.5

at 15000C/ 2 hrs |

37 |

1580 |

Reheating furnace hearth |

| SR-90 LF |

90 |

0.5 |

18 |

2.92 |

600 |

± 0.2

at 15000C/ 2 hrs |

38 |

1700 |

Carbon black reactor |

| SR-95 |

95 |

0.5 |

22 |

3.00 |

600 |

± 0.2

at 15000C/ 2 hrs |

38 |

1700 |

Secondary Steel making Vessel, Chemical,

Petrochemical & Fertilizer application. |

|

| |

|

|

|